1. Effectively control the temperature:

The cold air cooling system quickly removes the heat generated inside the motor and dissipates it to the surrounding environment through the precisely designed air duct structure and efficient heat dissipation elements. This process not only ensures that the motor will not overheat during continuous high-load operation, but also avoids performance degradation and efficiency loss caused by high temperature. Under extreme working conditions, the cold air cooling system can automatically adjust the cooling air volume to ensure that the motor temperature is always kept within a safe range, thereby effectively extending the service life of the motor. By precisely controlling the temperature, the cold air cooling system provides a stable and reliable working environment for the motor, reducing mechanical stress and material aging problems caused by temperature fluctuations.

2. Reduce thermal stress:

During the long-term operation of the motor, the internal components will generate heat due to the passage of current and mechanical friction, thereby generating thermal stress. These thermal stresses will accelerate the aging, deformation and cracking of the material, thereby shortening the service life of the motor. The cold air cooling system reduces the internal temperature of the motor by taking away the heat in time, significantly reducing the generation of thermal stress. This effect of reducing thermal stress not only protects the key components of the motor, such as the winding and insulation layer, but also improves the structural stability of the entire motor, ensuring that the motor can operate stably for a long time in harsh environments.

3. Prevent overheating damage:

Overheating is one of the common causes of motor damage. When the motor temperature exceeds its design limit, it may lead to serious consequences such as failure of insulation materials, winding short circuit or damage to mechanical components. The cold air cooling system effectively prevents the occurrence of motor overheating by monitoring the motor temperature in real time and adjusting the cooling air volume. This system not only improves the operating safety of the motor, but also reduces the downtime and maintenance costs caused by overheating. While protecting the motor from overheating damage, the cold air cooling system also ensures that the motor can continue to provide stable power output.

4. Improve insulation performance:

Insulation performance is an important guarantee for the safe operation of the motor. In a high temperature environment, the insulation material is prone to aging, cracking and losing insulation effect, which can cause electrical failures. The cold air cooling system reduces the aging rate of the insulation material by reducing the motor temperature and improving its insulation performance. This effect of improving insulation performance not only enhances the electrical safety performance of the motor, but also extends the service life of the insulation material. Under the protection of the cold air cooling system, the insulation performance of the motor has been significantly improved, ensuring the stable and reliable operation of the motor in various working environments.

5. Reduce maintenance costs:

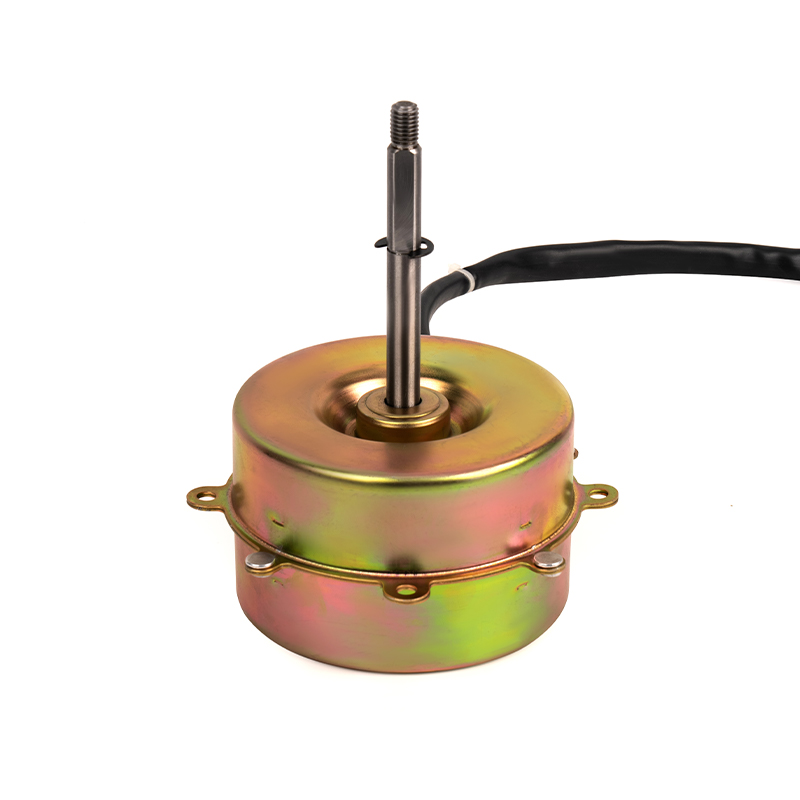

The cold air cooling system significantly reduces the maintenance cost of the motor by extending the service life of the motor and reducing the failure rate. Since the motor runs at a lower temperature, the wear and damage caused by high temperature are reduced, thus reducing the number of repairs and replacement parts. In addition, the cold air cooling system also improves the operating efficiency and stability of the motor and reduces production losses caused by downtime for maintenance. The combined effect of these advantages makes the motor with the cold air cooling system have lower maintenance costs and higher economic benefits throughout its service life. For the DC air cooler motor independently developed by Mido Motor Factory in 2024, its high-quality materials and strict quality control process further enhance these advantages of the cold air cooling system.

English

English عربى

عربى ++86 13524608688

++86 13524608688