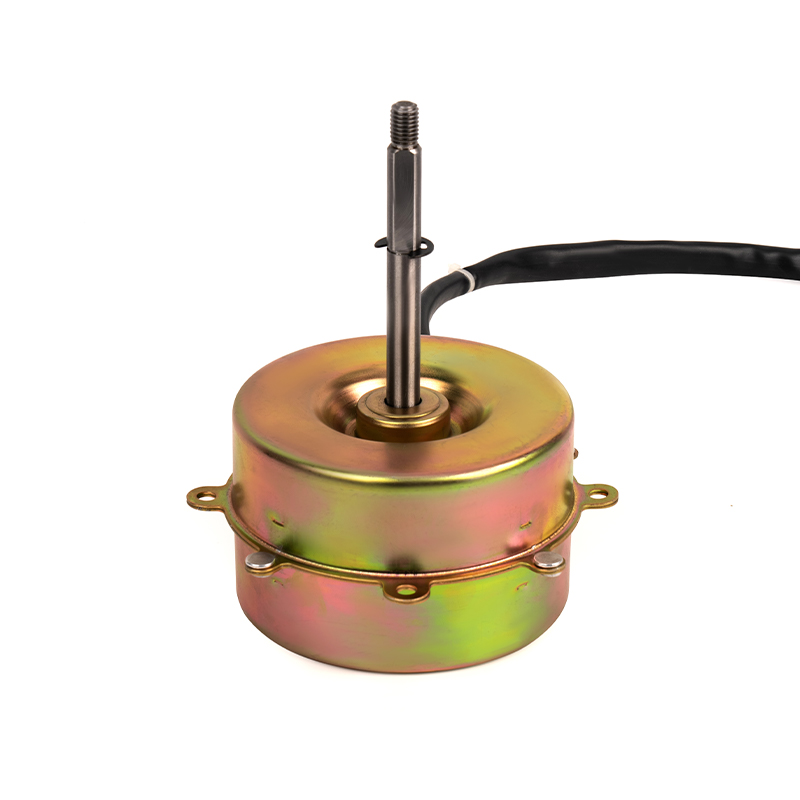

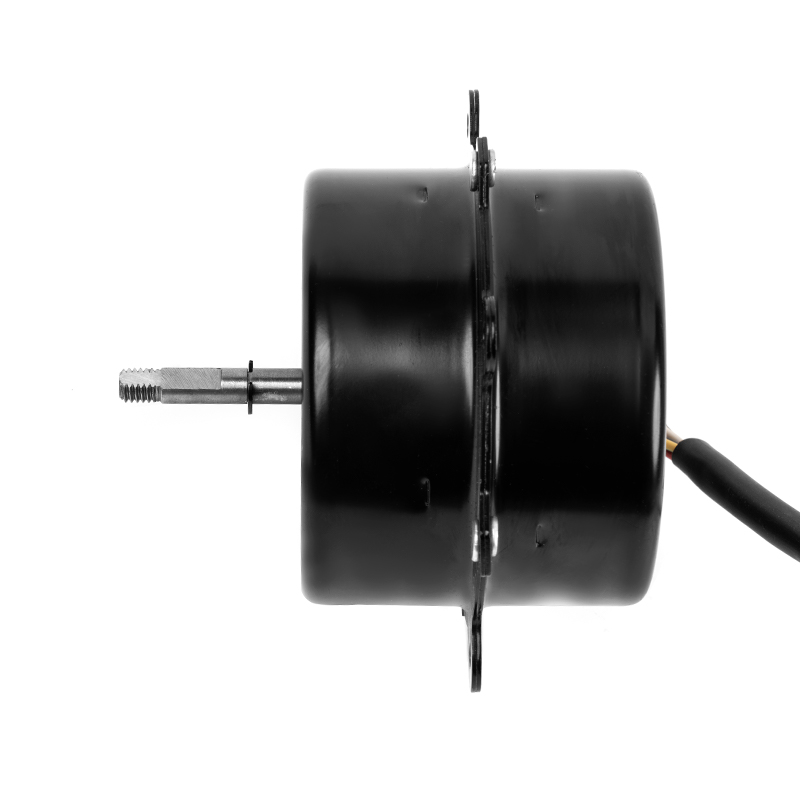

What is the starting method of YSY-140 (658) Desktop Single-Phase Cold Air AC Motor, 1.3A?

YSY-140 (658) is a single-phase cold air AC motor with excellent performance. Its starting method is a crucial part of its design. In industrial applications, the starting method of the motor directly affects the performance, efficiency and life of the motor.

YSY-140 (658) motor is powered by a single-phase power supply, so single-phase starting method is usually adopted. The starting methods of single-phase motors include direct starting, star-delta starting, autotransformer starting and capacitor starting. Among them, capacitor starting method is the most common and widely used method, and it is also one of the common starting methods of YSY-140 (658) motors.

The capacitor starting method improves the starting torque and starting efficiency of the motor by connecting a starting capacitor in series. During the starting process, the capacitor generates an auxiliary phase difference, making it easier for the motor to start and reach the rated speed. This starting method is suitable for occasions that require a large starting torque. It can effectively reduce the starting current of the motor, extend the life of the motor, and improve the efficiency and performance of the motor.

In addition, the starting method of the YSY-140 (658) motor can be customized according to specific application requirements. Users can choose starting capacitors of different capacities as needed to meet the requirements under different loads and starting conditions. At the same time, users can also choose different starting controllers, such as soft starters or inverters, according to specific application scenarios to achieve more precise starting control and more efficient operation.

What is the quality control standard of this motor?

YSY-140 (658) Desktop Single-Phase Cold Air AC Motor, 1.3A is a high-performance single-phase cold air AC motor. Its quality control standard is a key factor in ensuring product quality and stable performance. The quality control standard covers a series of specifications and processes in the product design, production, testing and delivery process, aiming to ensure that the product meets customer needs and international standards, while ensuring product reliability, stability and safety.

The quality control standards for YSY-140 (658) motors mainly include the following aspects:

Design standards are the basis of quality control, covering aspects such as the motor's structural design, material selection, and process requirements. Design standards must comply with relevant international standards and industry specifications to ensure that the motor's performance and reliability meet the expected level.

Production standards require that a series of production standards and process flows be strictly implemented during the production process, including material procurement, processing and manufacturing, assembly and commissioning, etc. Production standards ensure product consistency and stability, and avoid product quality problems caused by errors in the production process.

Testing standards require that the motor be strictly tested and inspected after production is completed to verify whether the product's performance and quality meet the requirements. Testing standards include static tests (such as insulation resistance, insulation strength, etc.) and dynamic tests (such as rated load operation, starting performance, etc.) to ensure that the product operates normally under various working conditions.

Certification standards generally require that YSY-140 (658) motors be certified by international certification bodies, such as CE certification, UL certification, etc., to prove that the product meets relevant quality standards and safety requirements. These certification standards are authoritative verification of product quality and performance, and are also important credentials for products to enter the international market.

English

English عربى

عربى

+86 13524608688

+86 13524608688