1. Basic Principles and Applications of Single-Phase Cold Air AC Motor

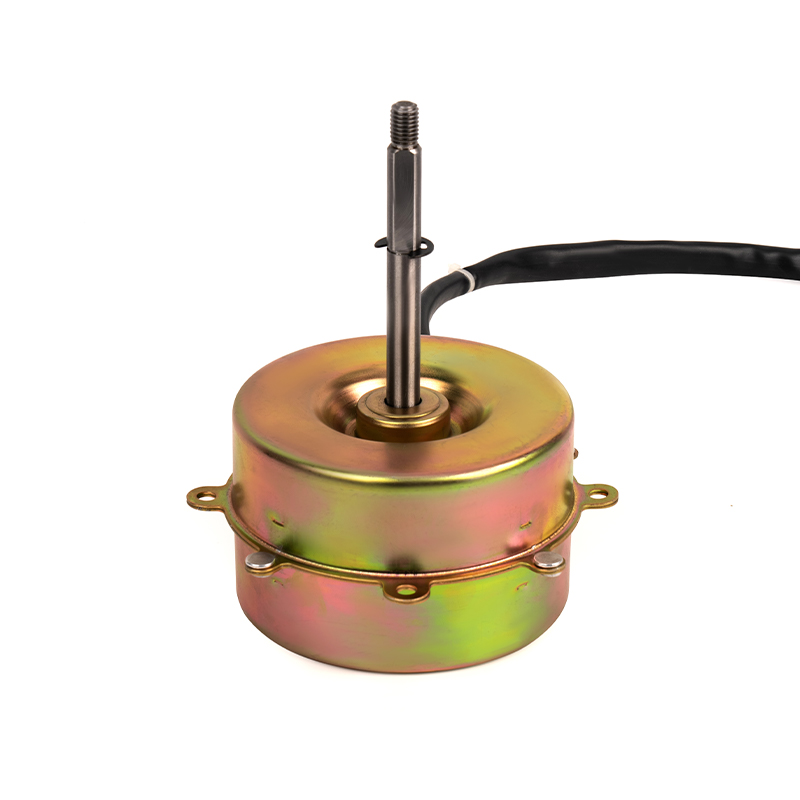

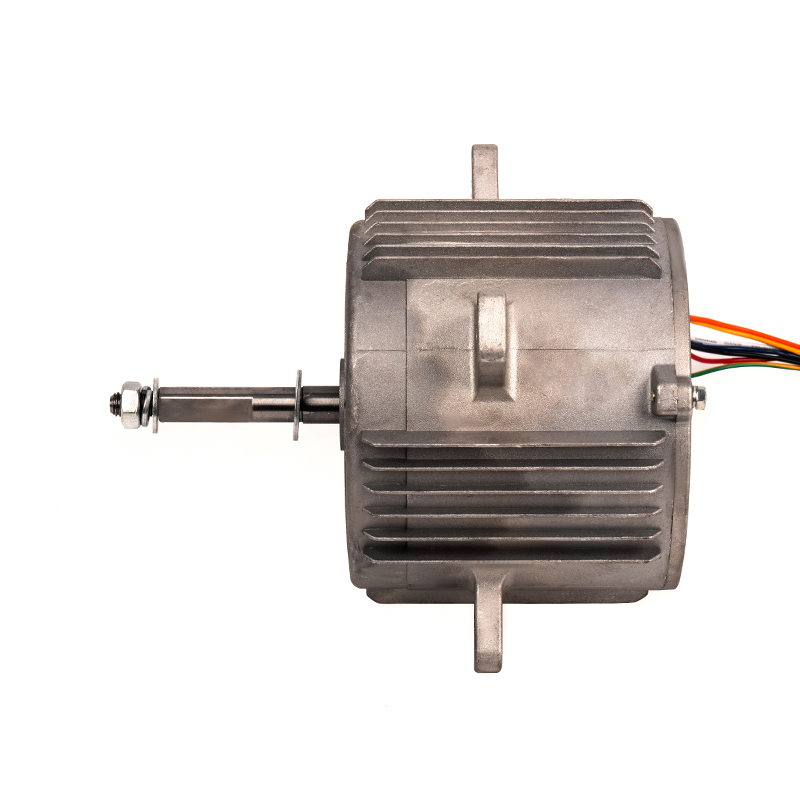

YSY-250-4 Desktop Single-Phase Cold Air AC Motor is an electric motor driven by a single-phase AC power supply, which is widely used in cold air systems and air conditioning equipment. Its basic principle is based on electromagnetic induction, which drives the rotor to rotate by generating a rotating magnetic field between the stator and the rotor. The stator winding of a single-phase motor usually consists of two sets of coils, one main winding and one auxiliary winding. The main winding is directly connected to the power supply, and the auxiliary winding is connected to the power supply through a starting capacitor. The starting capacitor provides a phase shift when the motor starts, thereby generating a rotating magnetic field to start the motor to rotate.

Single-phase cold air AC motors are widely used in household air conditioners, commercial air conditioners and some industrial cooling equipment. Household air conditioners are one of the most common applications of single-phase motors. In air conditioners, single-phase motors are mainly used to drive compressors and fans. The function of the compressor is to compress the refrigerant into a high-temperature and high-pressure gas, and then dissipate the heat through the condenser, and the refrigerant is liquefied again to achieve the purpose of refrigeration. The fan motor is used to draw the hot air in the room into the air conditioner, cool it through the evaporator, and then blow the cold air back to the room. Single-phase motors also play a similar role in commercial air conditioners and industrial cooling equipment, achieving cooling and ventilation by driving compressors and fans.

The application of single-phase cold air AC motors is not limited to air conditioning equipment, but also includes some small cooling equipment, such as refrigerators, freezers and water dispensers. In these equipment, single-phase motors are also used to drive compressors and fans to achieve refrigeration and cooling functions. In addition, single-phase motors are also used for cooling in some industrial equipment, such as generators, transformers and cooling systems of electronic equipment.

The reason why single-phase motors are widely used in air conditioning equipment is mainly because they are easy to start, run smoothly and are easy to maintain. The starting capacitor design of single-phase motors enables them to start at low voltage, which is particularly important for home and small commercial equipment. During operation, single-phase motors have low noise and low vibration, which is suitable for occasions that require a quiet environment. In addition, single-phase motors have a simple structure, fewer parts, low repair and maintenance costs, and a long service life.

2. Advantages and technical features of single-phase cold air AC motors

YSY-250-4 Desktop Single-Phase Cold Air AC Motor is widely used in air conditioning equipment, mainly due to its many advantages and technical features. Compared with other types of motors, single-phase motors have many unique advantages that make them irreplaceable in specific applications.

Single-phase motors are easy to start. This is one of the most significant advantages of single-phase motors. When the motor starts, the starting capacitor generates a rotating magnetic field by providing phase displacement, allowing the motor to start quickly. This starting method enables single-phase motors to start easily under low voltage conditions, making them very suitable for use in homes and small commercial equipment. In addition, single-phase motors do not require complex starting equipment and control circuits when starting, which simplifies the design and manufacture of motors and reduces costs.

Single-phase motors run smoothly. During the operation of a single-phase motor, the rotor runs smoothly under the action of a rotating magnetic field, with low noise and low vibration. This feature makes single-phase motors particularly suitable for occasions that require a quiet environment, such as homes, offices, and hospitals. In addition, the smooth operation of single-phase motors also reduces mechanical wear, extends the service life of the motor, and improves the reliability of the equipment.

Single-phase motors are easy to maintain. Single-phase motors have a simple structure, mainly consisting of a stator, a rotor, and a starting capacitor, with fewer parts and a low failure rate. Even if a failure occurs, repairs are relatively simple, and only the faulty parts need to be replaced. During the maintenance process, no complex professional equipment and technology are required, and users can perform simple maintenance and care by themselves. This not only reduces maintenance costs, but also improves the efficiency of equipment use.

The technical features of single-phase air conditioner AC motors include efficient electromagnetic design, precise processing technology and high-quality material selection. These technical features ensure the reliability and stability of the motor under various working conditions. The efficient electromagnetic design improves the magnetic field utilization and power conversion efficiency of the motor by optimizing the geometric structure of the stator and rotor. The precise processing technology ensures the dimensional accuracy and assembly quality of the motor parts and reduces mechanical loss and electromagnetic loss. The high-quality material selection improves the wear resistance, corrosion resistance and insulation performance of the motor and extends the service life of the motor.

Modern single-phase motors also use advanced control technologies such as frequency conversion control and intelligent control. Frequency conversion control technology achieves precise control of the motor speed by adjusting the operating frequency of the motor, thereby improving the operating efficiency and energy saving effect of the motor. Intelligent control technology monitors the operating status of the motor in real time through sensors and control systems, automatically adjusts the operating parameters of the motor, and optimizes the operating performance of the motor. These advanced control technologies further improve the performance and energy efficiency of single-phase motors, making them more widely used in modern air conditioners.

3. Development Trend and Market Prospect of Single-Phase Cold Air AC Motor

With the global energy crisis and the enhancement of environmental awareness, the development of YSY-250-4 Desktop Single-Phase Cold Air AC Motor is also facing new challenges and opportunities. In the future, the development trend of single-phase motors will mainly focus on the following aspects:

Improving the energy efficiency of motors is an important direction for future development. At present, global energy is tight, and energy conservation and emission reduction have become the common goals of governments and enterprises. The energy efficiency of single-phase motors is mainly achieved by optimizing electromagnetic design, adopting new materials and improving manufacturing processes. Optimizing electromagnetic design includes improving the geometric structure of stators and rotors, increasing the utilization rate of magnetic conductive materials, reducing magnetic flux leakage, and improving the efficiency of power conversion. The application of new materials, such as high-efficiency core materials and high-conductivity wire materials, can significantly reduce the electromagnetic loss and mechanical loss of motors. In addition, advanced manufacturing processes, such as precision machining and automated assembly, can also improve the manufacturing quality and consistency of motors and further improve the energy efficiency of motors.

The application of intelligent control technology will make single-phase motors more efficient, flexible and reliable. Through the Internet of Things and big data technology, remote monitoring and intelligent adjustment of motors can be realized to improve the overall operating efficiency of equipment. Intelligent control technology includes variable frequency control, digital control and adaptive control. Variable frequency control technology can achieve precise control of motor speed and power by adjusting the operating frequency of the motor, optimize the motor's operating performance and energy saving effect. Digital control technology uses microprocessors and digital signal processors to achieve real-time monitoring and adjustment of the motor's operating status to ensure that the motor operates under optimal conditions. Adaptive control technology can achieve adaptive adjustment of different working conditions by learning and adjusting the motor's operating parameters, thereby improving the motor's operating stability and reliability.

In the motor manufacturing process, the use of environmentally friendly materials and green manufacturing processes will become a future development trend. Many materials and processes used in traditional motor manufacturing have certain pollution to the environment, such as the use of harmful metals and chemicals. In the future, the application of environmentally friendly materials, such as lead-free welding, halogen-free insulation materials and degradable materials, will reduce environmental pollution and achieve sustainable development. Green manufacturing processes can reduce environmental impacts in the manufacturing process and improve resource utilization efficiency by reducing energy consumption and waste emissions. In addition, the application of recycling and reuse technologies can reduce the burden of discarded motors on the environment and promote the development of a circular economy.

English

English عربى

عربى

+86 13524608688

+86 13524608688