How Speed Control Works:

Electronic Speed Control: DC motors employ sophisticated electronic controllers that modulate the power supplied to the motor. By varying the voltage or current, these controllers adjust the motor's rotational speed. Unlike AC motors, which generally operate at fixed speeds dictated by the frequency of the electrical supply, DC motors can operate at a range of speeds, offering precise control.

Pulse Width Modulation (PWM): Pulse Width Modulation is a common technique used in range hoods to regulate DC motor speed. PWM involves switching the motor's power supply on and off rapidly, creating an average voltage that controls the motor's speed. By adjusting the duty cycle (the proportion of time the power is on versus off), the speed of the motor can be finely tuned. This method allows for smooth and efficient speed adjustments, ensuring that the motor operates within the desired performance range.

Feedback Mechanism: Advanced range hoods integrate sensors that provide real-time feedback on the motor's speed and performance. These sensors monitor various parameters such as airflow rate and motor load. The electronic controller uses this data to make continuous adjustments to the motor's speed, ensuring consistent performance and optimal operation under varying conditions. This feedback loop enhances the precision of speed control and maintains effective ventilation.

Impact on Performance:

Energy Efficiency: DC motors equipped with variable speed controls offer superior energy efficiency compared to traditional fixed-speed AC motors. By adjusting the motor speed to match the ventilation requirements, the range hood minimizes energy consumption during less demanding conditions. This dynamic adjustment reduces overall electricity usage and can lead to significant cost savings on energy bills while also contributing to environmental sustainability.

Noise Levels: The ability to adjust the motor speed allows for a reduction in noise levels. At lower speeds, the motor produces less operational noise, contributing to a quieter kitchen environment. This is particularly advantageous in residential settings where noise reduction is a priority, enhancing the overall comfort and tranquility of the cooking space.

Airflow Management: Variable speed control enables precise management of airflow, which is crucial for effective ventilation. Users can tailor the airflow rate based on specific cooking activities, such as low-speed settings for simmering or high-speed settings for grilling and frying. This adaptability ensures that the range hood provides optimal smoke and odor removal, improving air quality and enhancing the cooking experience.

Extended Motor Life: Operating the motor at reduced speeds during periods of lower demand can mitigate wear and tear on the motor components. This gentle operation helps to extend the lifespan of the motor by minimizing stress and reducing the frequency of maintenance and repairs. The result is a more reliable and durable range hood with a longer service life.

User Control and Comfort: The flexibility of variable speed control empowers users to customize the ventilation performance to suit their individual preferences and cooking requirements. This level of control enhances user comfort by allowing adjustments to be made easily, ensuring that the range hood operates effectively across a range of cooking scenarios. The ability to fine-tune the ventilation settings contributes to a more pleasant and controlled kitchen environment.

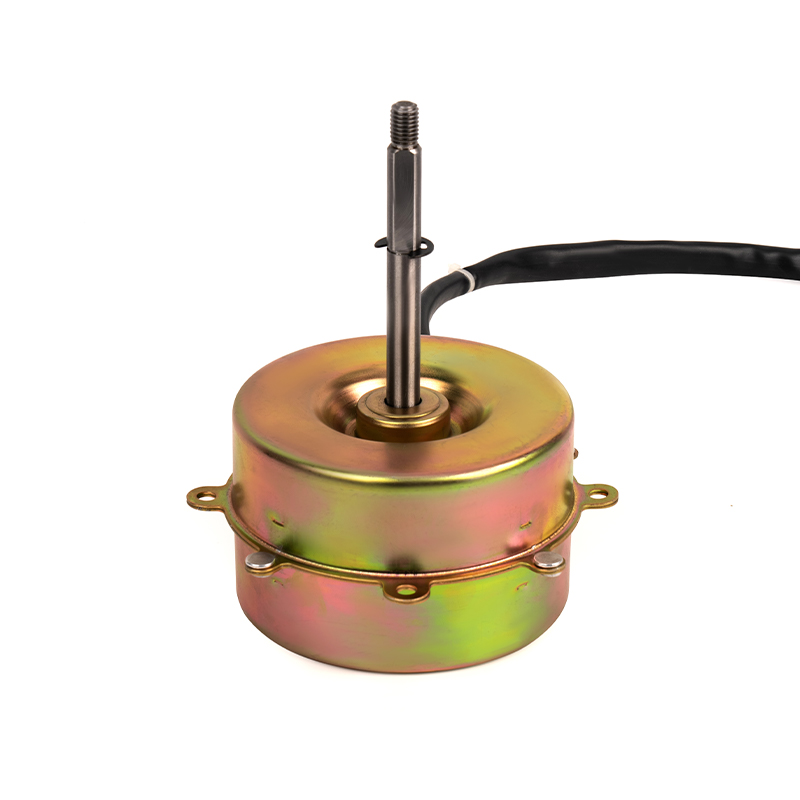

YSY-300-4 80cm Single-Phase Cooling Fan AC Motor, 1300rpm

English

English عربى

عربى ++86 13524608688

++86 13524608688