Heating AC Motors are engineered with advanced technologies that optimize their energy consumption. These motors often feature high-efficiency designs, such as improved winding insulation, optimized magnetic circuits, and reduced friction components, which collectively minimize energy losses during operation. By consuming less electrical energy to achieve the same heating output, these motors decrease the overall demand for electricity. Given that a significant portion of global electricity is still generated from fossil fuels, any reduction in energy consumption directly leads to lower carbon emissions. The use of variable frequency drives (VFDs) in Heating AC Motors allows them to operate at varying speeds, further enhancing efficiency by matching motor output to the exact heating requirements of the system at any given time.

Heating AC Motors are often integrated with sophisticated control systems that enable them to adjust their speed and power output dynamically based on the specific heating demands of the environment. These systems can include sensors and automated controls that monitor factors such as ambient temperature, occupancy, and time of day. By precisely regulating the motor’s operation to meet real-time heating needs, these systems prevent energy wastage that would otherwise occur from running the motor at full capacity when it's not necessary. This targeted operation not only enhances comfort but also reduces the overall energy consumption of the heating system, thereby lowering associated carbon emissions.

In heating systems that rely on heat pumps, Heating AC Motors play a crucial role in optimizing the heat transfer process. Heat pumps work by moving heat from one location to another, rather than generating heat through the combustion of fossil fuels. By efficiently driving the compressor and other components of the heat pump, Heating AC Motors help maximize the system's coefficient of performance (COP), which is a measure of the efficiency of heat transfer. This high efficiency reduces the need for supplemental heating sources, such as natural gas or oil-fired boilers, thereby decreasing the overall consumption of fossil fuels and the carbon emissions associated with their combustion.

Heating AC Motors are increasingly being integrated with renewable energy systems, such as solar photovoltaic (PV) panels or wind turbines. These motors can be designed to operate efficiently with the variable output of renewable energy sources, making them ideal for use in systems that prioritize sustainability. When powered by clean energy, Heating AC Motors enable heating systems to operate with little to no carbon emissions, significantly reducing the overall environmental impact. Smart grid technology can be employed to optimize the timing of motor operation to coincide with periods of peak renewable energy availability, further enhancing the carbon-reducing potential of the system.

Heating AC Motors are typically built with high-quality materials and designed for durability, leading to longer operational lifespans compared to standard motors. This longevity reduces the frequency of replacements, which in turn minimizes the environmental impact associated with manufacturing, transportation, and disposal of motor components. By extending the lifespan of the heating system, these motors contribute to a reduction in the overall resource consumption and waste generation, thereby decreasing the carbon footprint of the entire heating system lifecycle. The reduced need for manufacturing new motors translates into lower industrial emissions, further supporting global carbon reduction efforts.

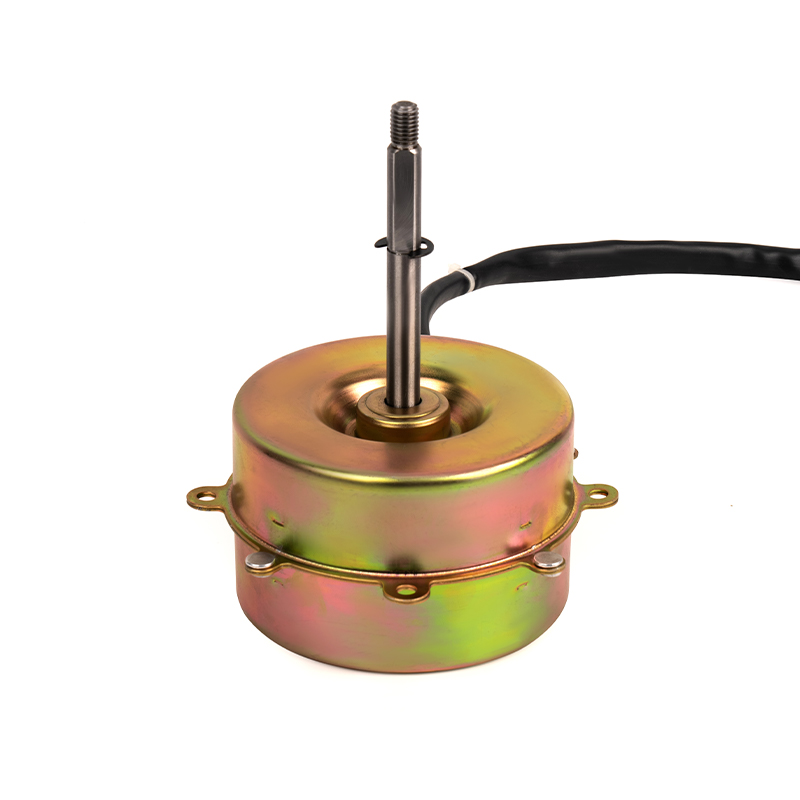

YSY-110 Single-Phase Cold Air AC Motor, 1300rpm

English

English عربى

عربى ++86 13524608688

++86 13524608688