The impact of a Cold Air AC Motor on overall air conditioning performance can be significant in several ways:

Improved Efficiency: Cold Air AC Motors are engineered to optimize energy use, leveraging advanced design and materials to minimize energy loss. By operating at higher efficiency levels, these motors consume less electricity to achieve the same cooling output as traditional motors. This enhanced efficiency not only reduces operational costs but also contributes to lower energy consumption, which is particularly beneficial in large-scale commercial or industrial settings where air conditioning demands are substantial.

Enhanced Cooling Capacity: The advanced design of Cold Air AC Motors allows for more consistent and powerful airflow, which directly enhances the cooling capacity of the air conditioning system. This capability ensures that the system can quickly reach and maintain the desired temperature even during peak demand periods. Enhanced cooling capacity is especially critical in environments requiring stringent temperature control, such as data centers, hospitals, and manufacturing facilities.

Better Temperature Control: Cold Air AC Motors often feature advanced control mechanisms, such as variable speed drives, that allow for precise modulation of motor speed and airflow. This precise control facilitates finer adjustments to the cooling process, resulting in more stable and comfortable indoor temperatures. Enhanced temperature control helps maintain a consistent climate, improving occupant comfort and preventing the temperature fluctuations that can occur with less sophisticated systems.

Reduced Wear and Tear: The design efficiency and operational smoothness of Cold Air AC Motors reduce the mechanical and thermal stress on the air conditioning system. By operating more smoothly and efficiently, these motors lessen the frequency and severity of wear and tear on system components. This reduction in strain extends the lifespan of both the motor and the overall system, decreasing the frequency of maintenance interventions and associated downtime.

Lower Noise Levels: Many Cold Air AC Motors are built with noise reduction in mind, incorporating design features that minimize operational noise. This can include precision engineering of motor components, use of sound-dampening materials, and optimization of airflow paths to reduce turbulence and vibration. The result is a quieter operation, which enhances the comfort of indoor environments by reducing the background noise associated with air conditioning systems.

Enhanced Air Quality: With superior airflow management capabilities, Cold Air AC Motors can significantly improve indoor air quality. Efficient airflow ensures that air is circulated more effectively, which helps in the even distribution of conditioned air and the removal of contaminants. Improved air circulation can also enhance the performance of air filters, leading to better removal of dust, allergens, and other pollutants, thereby contributing to a healthier indoor environment.

Cost Savings: The cumulative benefits of improved efficiency, enhanced cooling capacity, and reduced maintenance requirements lead to substantial cost savings over the lifetime of the air conditioning system. Lower energy bills are the most immediate financial benefit, but reduced maintenance costs and longer system lifespan also contribute to the overall cost-effectiveness of using Cold Air AC Motors. These savings can be particularly significant in commercial and industrial applications where large-scale air conditioning systems are in continuous operation.

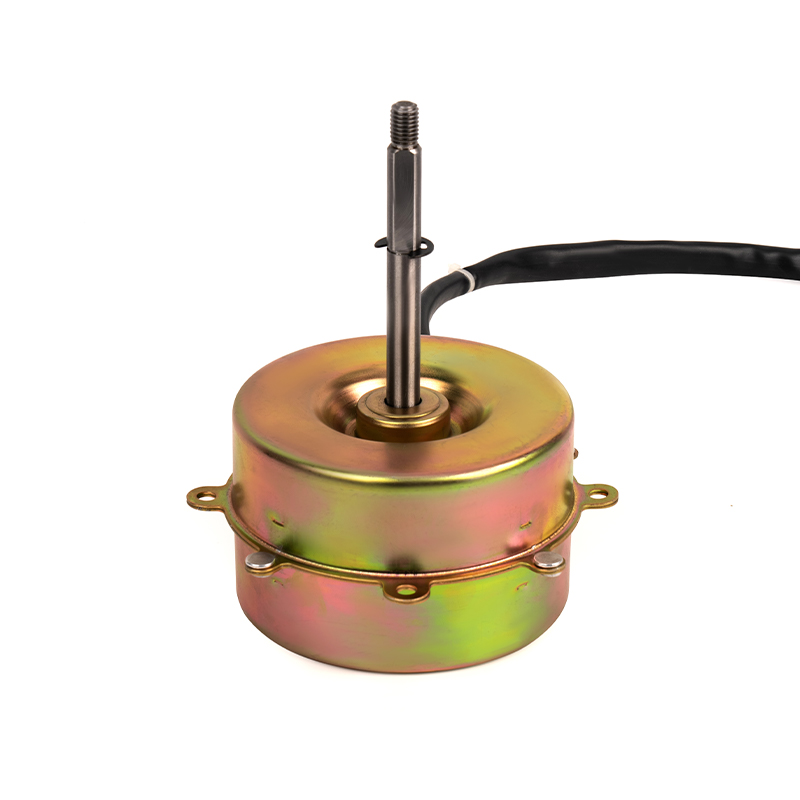

YSY-140 (658) Desktop Single-Phase Cold Air AC Motor, 1.3A

English

English عربى

عربى ++86 13524608688

++86 13524608688