Clean or Replace Air Filters: Air filters are essential components in air conditioning systems, as they trap dust, pollen, and other particulates, preventing them from entering the unit and circulating throughout the room. Over time, these filters can become clogged, reducing airflow and forcing the motor to work harder, leading to increased energy consumption and potential overheating. To maintain optimal airflow and efficiency, it is crucial to inspect the filters regularly. If the filters are washable, they should be cleaned with water and mild detergent, then thoroughly dried before reinstallation. In environments with high levels of dust or allergens, more frequent filter maintenance may be necessary.

Inspect and Clean the Coils: The evaporator and condenser coils are critical components responsible for heat exchange in the air conditioning process. The evaporator coil absorbs heat from the indoor air, while the condenser coil releases it outside. Dirt and debris accumulation on these coils can act as insulation, impeding heat transfer and reducing the system's cooling efficiency. This buildup can also lead to increased pressure and temperature within the system, causing the motor to work harder and potentially overheat. To clean the coils, first, turn off the power to the unit. Then, use a soft brush or vacuum cleaner to remove loose debris. For more thorough cleaning, apply a specialized coil cleaner, following the manufacturer's instructions. Allow the cleaner to sit for the recommended time before rinsing with water. Regular coil cleaning, at least twice a year, helps maintain efficient operation and prevents potential damage to the motor and compressor.

Check for Refrigerant Leaks: Refrigerant is the working fluid in air conditioning systems that absorbs and releases heat during the cooling process. Maintaining the correct refrigerant level is crucial for efficient operation. Low refrigerant levels can cause the unit to struggle to cool the air, leading to increased energy consumption and strain on the motor. Signs of refrigerant leaks include diminished cooling capacity, ice formation on the evaporator coil, and unusual hissing sounds. The technician will use specialized equipment to detect leaks, repair any damaged components, and recharge the system with the correct amount of refrigerant, ensuring compliance with environmental regulations. Proper refrigerant management not only enhances cooling performance but also protects the environment by preventing the release of harmful substances.

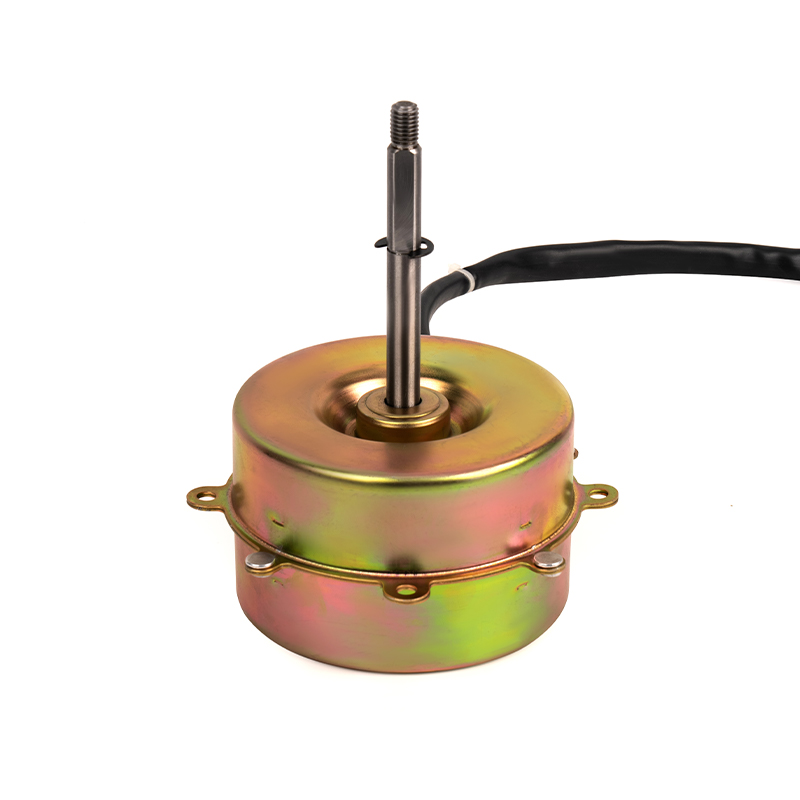

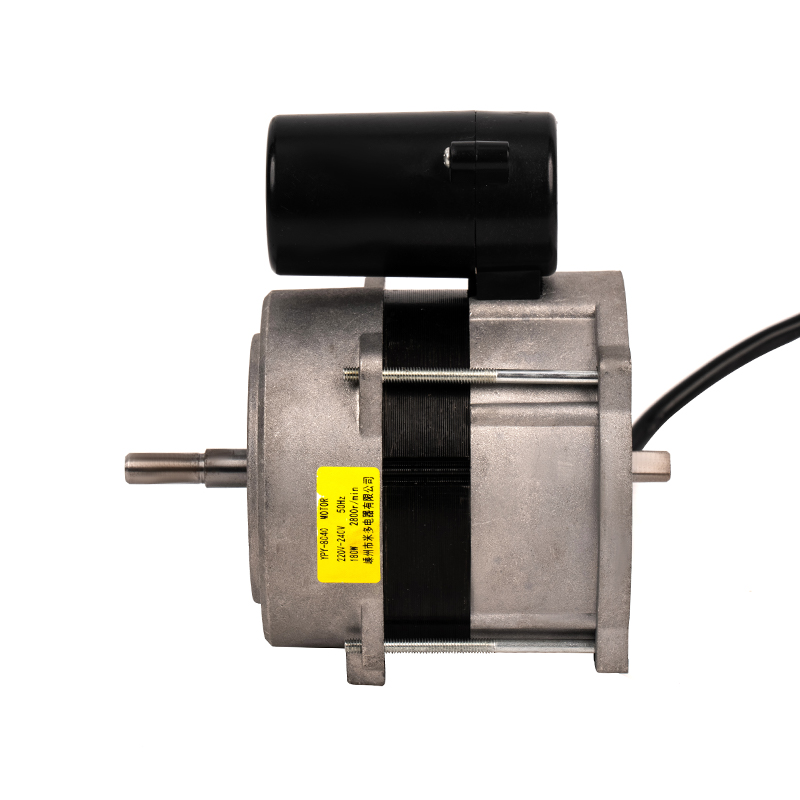

Lubricate Moving Parts: Lubrication is vital for reducing friction and wear on moving parts, such as fan bearings and motor components. Over time, these parts can become dry and generate heat, leading to premature wear and potential failure. To lubricate the components, first, consult the unit's maintenance manual for specific lubrication points and recommended lubricants. Apply a few drops to the designated lubrication ports or bearings, taking care not to over-lubricate, as excess oil can attract dirt and cause additional wear. Regular lubrication, typically once a year, helps ensure smooth operation, reduces noise levels, and extends the life of the motor and associated components.

Inspect the Motor and Electrical Wiring: Regular inspection of the motor and electrical wiring is essential to identify potential issues that could compromise the unit's safety and performance. Begin by visually inspecting the motor for signs of wear, such as discoloration, burn marks, or unusual odors. Check the electrical wiring for any signs of fraying, corrosion, or loose connections. Ensure that all electrical connections are tight and secure, as loose connections can cause arcing, leading to overheating and potential fire hazards.

YPY-8040 Capacitor Operation Heater Motor, 2800RPM

English

English عربى

عربى ++86 13524608688

++86 13524608688