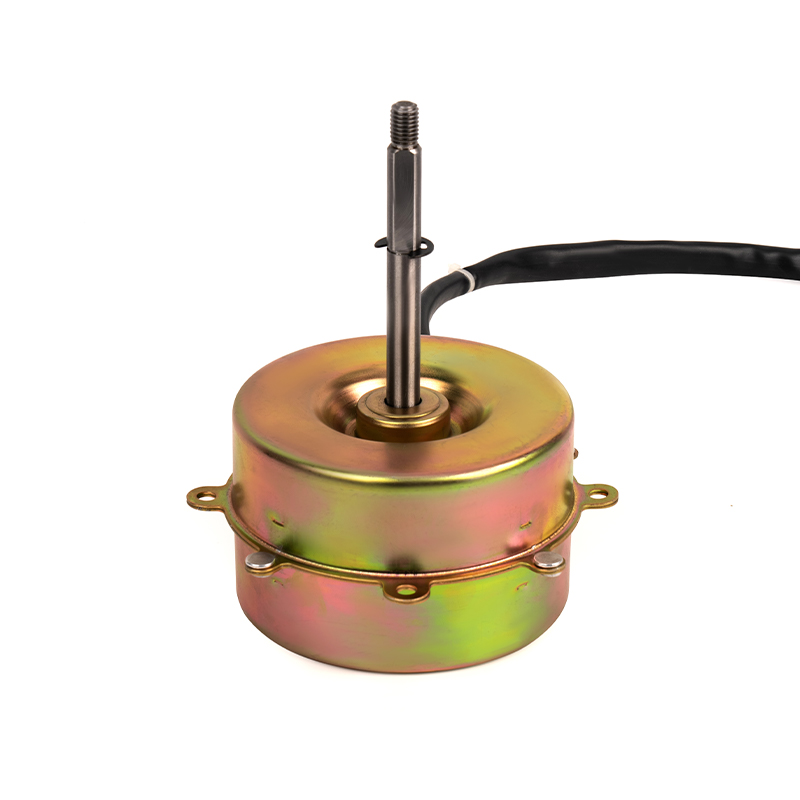

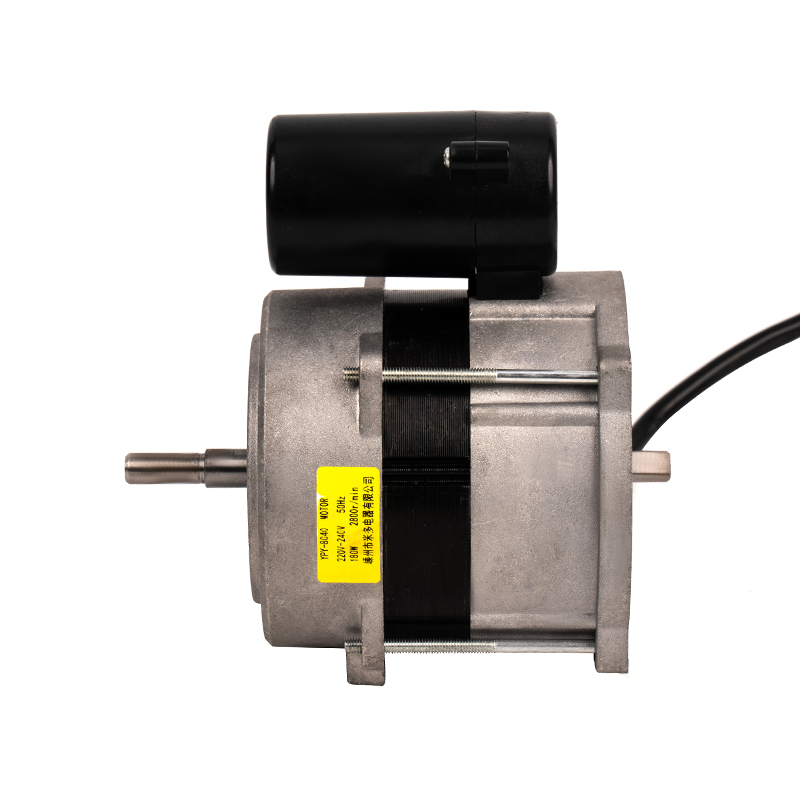

Working Principle of YPY-8040 Capacitor Operation Heater Motor, 2800RPM

In modern industrial and household appliances, motors are used everywhere, driving a variety of equipment, from simple fans to complex production line machinery. As a special motor that combines capacitor starting technology with heating function, the working principle of Capacitor Operation Heater Motor is unique and efficient.

1. Capacitor Starting Mechanism

The working principle of this part of capacitor starting is similar to that of traditional capacitor starting motors, mainly relying on the phase difference provided by the capacitor during the motor starting stage to enhance the starting torque. When the motor is stationary, since the rotor has not yet rotated, the rotating magnetic field generated by the stator winding cannot directly drive the rotor to rotate, because the induced current in the rotor is in phase with the stator magnetic field at this time, and cannot generate enough torque. To overcome this problem, motor designers introduced capacitors. The capacitor is connected in series with the auxiliary winding of the motor (also called the starting winding). When the motor is powered on, the capacitor provides a current that is 90 degrees out of phase with the main winding current. This phase difference makes the magnetic field generated by the auxiliary winding form a certain angle with the magnetic field of the main winding in space, thereby generating a rotating magnetic field force, namely the starting torque. This torque is sufficient to make the motor rotor start to rotate and gradually accelerate to the predetermined speed.

2. Heating mechanism

Unlike traditional capacitor starting motors, Capacitor Operation Heater Motor also integrates a heating function, which is usually achieved in the following ways.

Built-in heating element: Heating elements such as resistance wire and PTC heater may be installed inside the motor. These elements will heat up when powered on, thereby transferring heat to the motor housing or surrounding medium. The power and temperature of the heating element can be adjusted by the controller to meet different heating needs.

Heat conduction and convection: When the motor is running, a certain amount of heat will be generated due to the current passing through the winding and the core. In the Capacitor Operation Heater Motor, this naturally generated heat can be effectively utilized, and by optimizing the heat dissipation structure of the motor, more heat can flow to the area that needs to be heated.

3. Comprehensive application of working principles

In practical applications, the capacitor starting mechanism and heating mechanism of the Capacitor Operation Heater Motor complement each other. When the motor starts, the capacitor provides the necessary phase difference to enhance the starting torque, while the heating element starts to work and provides heat to the motor or the surrounding environment. As the motor speed gradually stabilizes, the capacitor is automatically disconnected (through a centrifugal switch), the motor enters normal operation, and the heating element continues to work to adjust the temperature as needed. This design gives the Capacitor Operation Heater Motor a significant advantage in situations where both power and heating are required. For example, in the outdoor unit of the air conditioning system, the motor is not only responsible for driving the compressor, but also provides heat to melt the frost on the condenser during the defrosting process; in the heater, it can simultaneously blow out warm air and provide necessary power support.

English

English عربى

عربى

+86 13524608688

+86 13524608688