What is the main role of the capacitor in the capacitor-operated asynchronous motor?

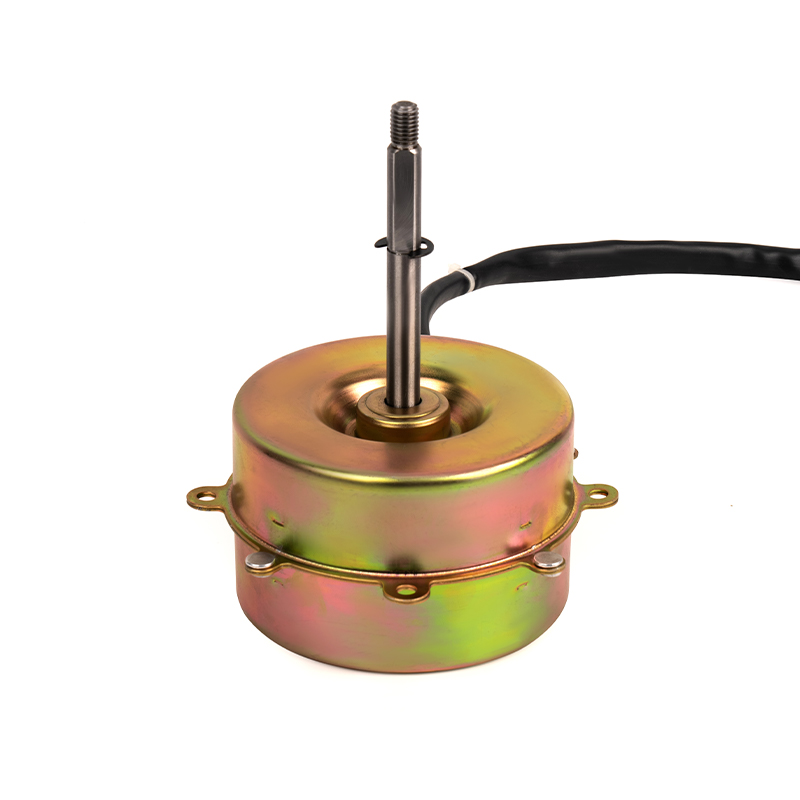

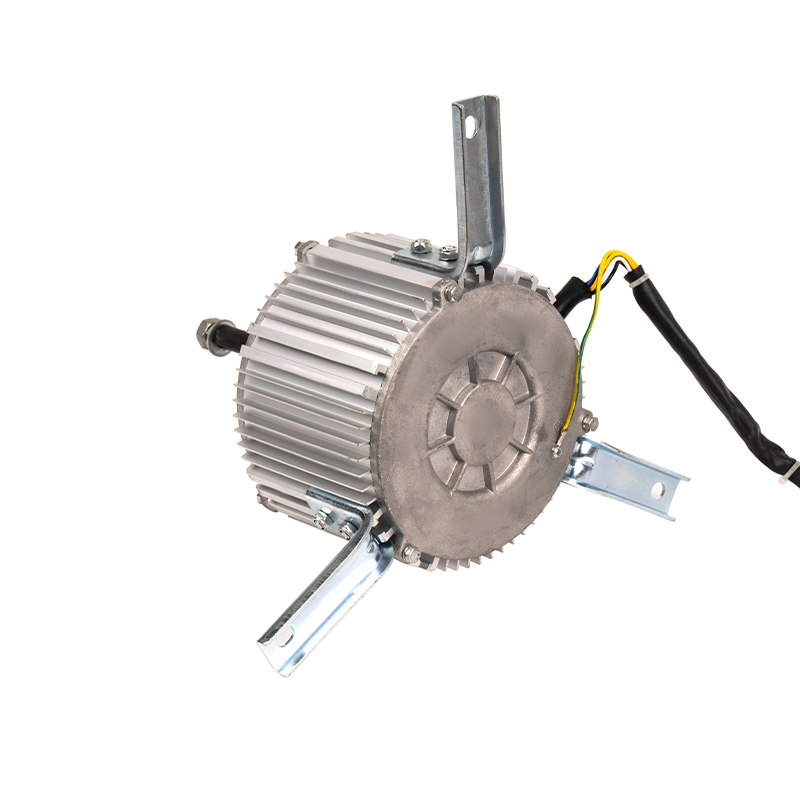

From starting to stable operation, capacitors play an indispensable role in the working process of YSY-250-4 Fan With Capacitor Run Asynchronous Motor. As an important power source widely used in household appliances, industrial equipment, ventilation systems and other fields, the efficiency and reliability of capacitor-run asynchronous motors are directly related to the performance of the entire system. As the key "catalyst" in this system, the function of capacitors far exceeds the scope of simple electrical components. It profoundly affects the starting characteristics, operating efficiency and long-term stability of the motor.

When the motor is stationary, it is not only the static friction between mechanical parts that needs to be overcome, but also the resistance caused by the inertia of the rotor when it is stationary. At this time, the capacitor cleverly changes the phase relationship between current and voltage in the motor circuit with its unique phase shifting ability. Specifically, the capacitor is connected in series to the starting coil (or auxiliary coil), and through its charging and discharging process, the current in the main coil (working coil) and the auxiliary coil has a phase difference of about 90 degrees. The existence of this phase difference makes the magnetic fields generated by the two coils no longer simply superimposed, but interlaced to form a rotating magnetic field. This rotating magnetic field is the key force that drives the motor rotor to rotate from a stationary state.

Capacitors can provide instantaneous large current at the moment of starting. This large current, like a powerful thrust, helps the motor quickly overcome the resistance at the time of starting, so that the rotor can reach a higher speed in a short time, and then approach or even reach the rated speed of the motor. In this process, the capacitor not only demonstrates its ability to respond quickly, but also ensures the smooth and rapid start of the motor through its current amplification effect.

After the motor is successfully started and enters the stable operation stage, the role of the capacitor has not weakened, but has become more important. At this stage, the capacitor significantly optimizes the operating efficiency of the motor through its reactive compensation characteristics. In the AC circuit, due to the presence of inductive elements (such as motor coils), there is often a phase difference between current and voltage, resulting in a part of the electrical energy being transferred back and forth between the power grid and the motor in the form of reactive power, and it cannot be effectively utilized. The addition of capacitors is like equipping this circuit with an "energy recycling station", which can absorb and store this part of reactive power and release it when needed, thereby reducing the reactive current in the power grid, reducing line losses, and improving the power factor of the motor.

In addition, capacitors also play a role in stabilizing current and voltage. During the operation of the motor, the current and voltage may fluctuate due to factors such as load changes and power supply voltage fluctuations. This fluctuation not only affects the operating efficiency of the motor, but may also cause damage to the motor. The capacitor, with its energy storage characteristics, can smooth these fluctuations to a certain extent, allowing the motor to operate in a more stable environment. This stability not only extends the service life of the motor, but also improves the reliability of the entire system.

In addition to the above functions, capacitors are also the nemesis of electromagnetic interference (EMI). During the operation of the motor, due to the rapid changes in the electromagnetic field, electromagnetic radiation may be generated, interfering with the normal operation of surrounding electronic equipment. The capacitor can absorb and consume this electromagnetic energy, reduce the generation of electromagnetic radiation, and thus improve the electromagnetic compatibility of the motor. This is particularly important in the environment where modern electronic equipment is dense, because it ensures that the motor does not interfere with each other when coexisting with other equipment, ensuring the stable operation of the entire system.

English

English عربى

عربى

+86 13524608688

+86 13524608688